How To Make A Rafter Seat Cut

Equally a immature carpenter (or should I say, "helper") I was e'er amazed at the skill of the roof framers. They fabricated it seem effortless to cutting and fit roof rafters with only the aid of a framing square. The whole process mystified me. In those early years, I tried several times to do it myself, merely I never had success. In time, an older carpenter named Rich Murphy took me up on a roof and helped me lay out and cutting a reverse gable using a framing square and his roofer's pocket reference or "bible." That experience sent me on the quest to master the art of roof cutting. I can't say I e'er mastered it, but I've come a long way since Rich graciously took the fourth dimension to help me empathise what was going on.

Of course, that was decades ago. Today, I apply a calculator to find rafter lengths and angles. Without a doubt, a construction computer is the quickest way to find your manner around a roof.

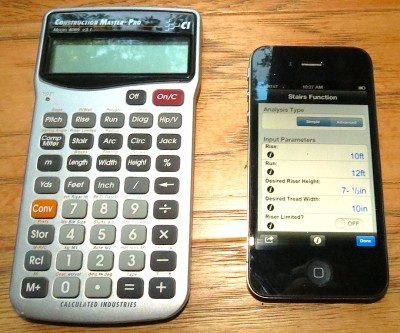

Side-by-side: The Construction Master Pro (left) and the BuildCalc app on an iPhone (right) (Note: Click any image to enlarge)

Construction calculators are pre-programmed with Pythagorean formulas for finding the values of correct triangles—and roofs are all about right triangles. These calculators eliminate some of the memorization, and all of the charts. They put all the data in a dainty, clean, easy-to-understand interface.

At that place are likewise ii commendable software versions available as smartphone apps: one from Calculated Industries, and i from BuildCalc. They essentially do the same affair as an actual construction calculator, but I prefer the real thing—if I'm going to drib a estimator in the mud, I'd rather information technology not be my pricey smartphone!

Using a Construction Computer

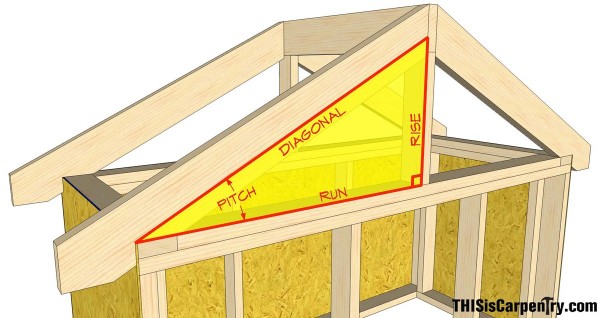

The values on the reckoner that we use for common roof framing are: Pitch, Rise, Run, and Diagonal. If you have any ii of those values, the calculator will quickly figure out the residuum of the right triangle—which means it will tell you everything else you need to know nearly a rafter.

Most of the time, the two values I have are the run of a building and a specified pitch, which is why I used these values for the instance in this online tutorial:

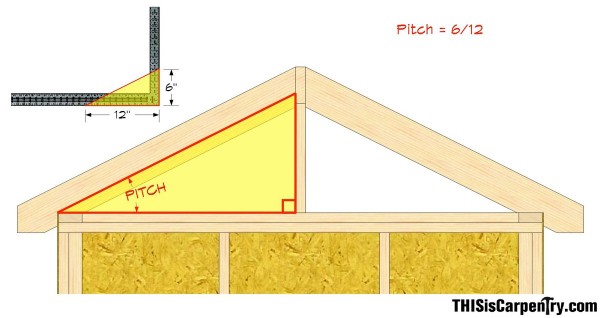

Looking at our model roof, I need to find the two elements that volition requite me all the information needed to frame the roof.

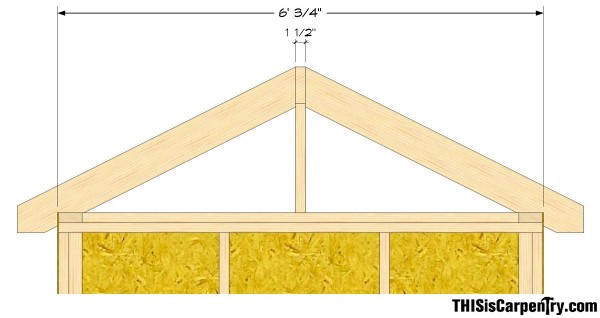

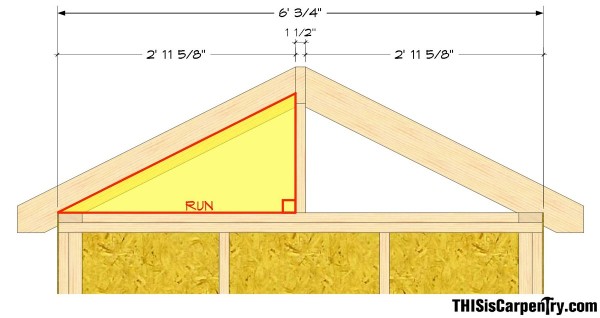

The edifice width, in this example, is half dozen ft. three/4 in., including the sheathing.

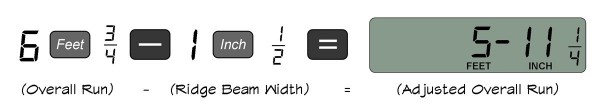

Each rafter but spans one-half the width of the building, and they first at the face of the ridge axle. For simplicity, and to forestall error, the first thing I do is deduct the total width of the ridge beam from the building width: in this example half dozen ft. iii/iv in. – i ½ in. = v ft. eleven 1/4 in.

I write this down on my template rafter as the adjusted overall run. Then, I divide that by 2 to get the bodily run of each rafter. The result on my Construction Primary calculator is ii ft. 11 5/viii in. Next, I press the Run key, instructing the calculator to utilize that dimension as the 'run,' which is the first element of the right triangle I am working with.

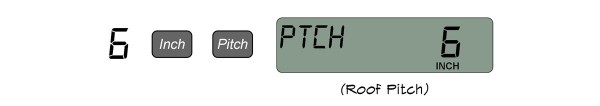

I demand i more than element, and in this instance I know the pitch of the roof, which is 6/12. Then I enter the number 6 into the reckoner, followed past the Inch key, and and so printing the Pitch primal. Annotation: Information technology'south important to remember to press the Inch key when inbound the roof pitch—without information technology, the calculator treats the number entered as 'degrees of pitch' instead of the ascension/run ratio of the roof.

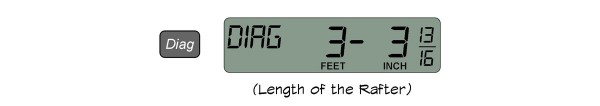

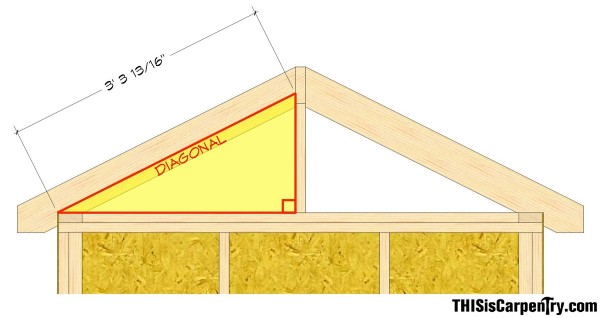

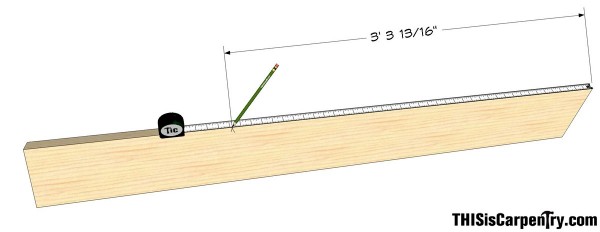

Now the calculator has all the details information technology needs, and information technology can provide me with every bit of information about that triangle. For instance, I'd too similar to know the diagonal measurement, which volition assistance me layout the seat cut. All I have to do is press the Diag fundamental, and the reckoner displays the measurement: 3 ft. three thirteen/xvi in. I write this measurement down on the template rafter, too.

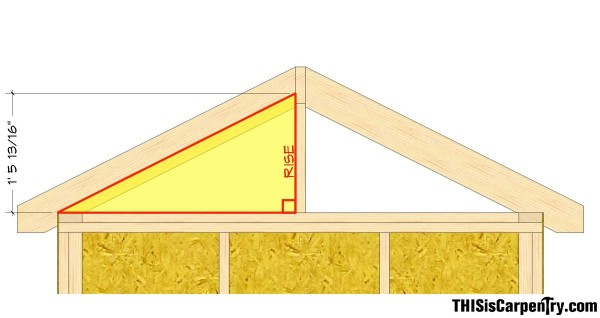

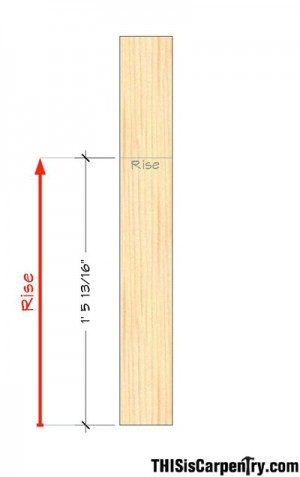

Adjacent, I press the Rise primal, and write that number downwardly: ane ft. 5 13/xvi in.

Adjacent, I press the Rise primal, and write that number downwardly: ane ft. 5 13/xvi in.

Be sure to become through all the calculations a few times, immigration the estimator in between. If all the results match, yous can rule out whatever keystroke errors.

The Layout

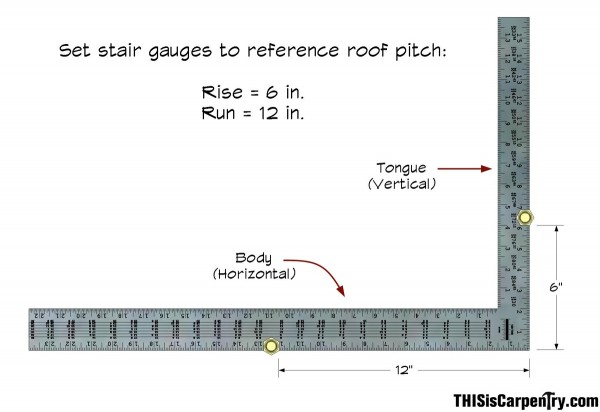

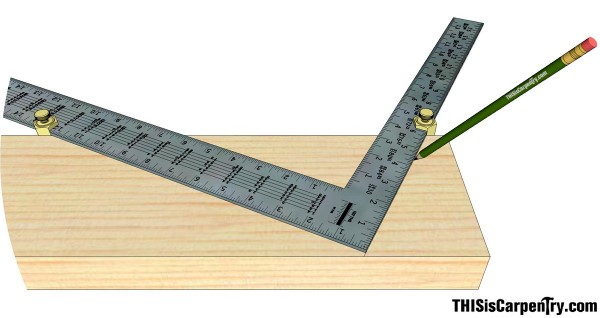

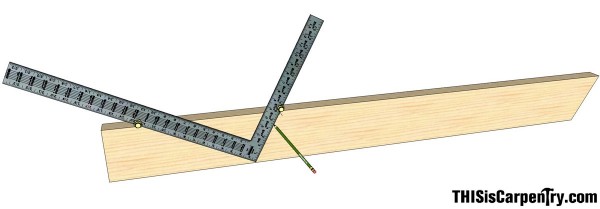

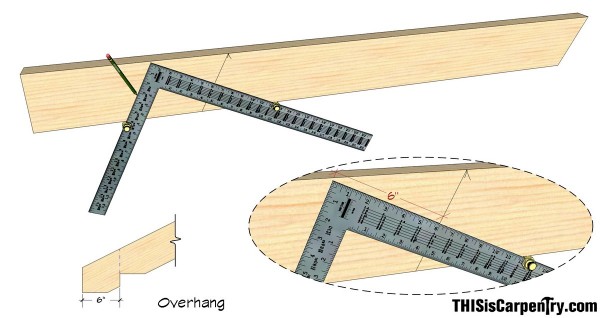

The next step is to layout and cut the rafter. First, I attach a set of stair gauges to my framing square, so I can brand precise, repetitive marks. In this example, I attach the gauges for a 6/12 pitch—half dozen in. on the tongue of the square and 12 in. on the body of the square. I advisedly align those measurements along the edge of the rafter cloth, and then fix the gauges.

Laying the square on the top of the rafter material, I commencement by scribing the plumb cut at the peak of the rafter. Keep in heed that, for most framing jobs, the tongue (the skinny side) is the vertical cut, and the body (the wider side) is the horizontal or seat cutting.

I brand this plumb cutting at the peak with my saw before marking my seat cutting (or "bird's oral fissure," in some vernacular). This way, I have something to claw my tape measure out on, which is very handy for long rafters.

Measuring from the tip of the rafter, I mark off the diagonal measurement forth the top edge of the rafter.

Then, using my framing square (some carpenters cull to use a speed square, but speed squares aren't every bit precise, especially on fractional pitches), I draw the parallel plumb line across the rafter, marking along the tongue of the foursquare. This line represents the plumb line on the rafter at the edge of the edifice.

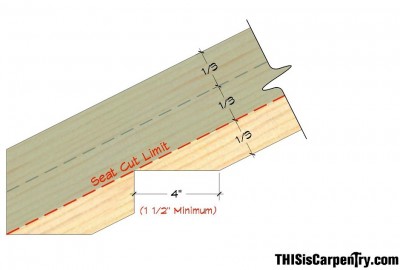

The seat cut (or "bird's mouth") is referenced from this line. If you are framing from scratch, and not matching rafter heights (which will exist explored in a time to come article), you will need to decide on what size the seat cutting should be. Most codes require a minimum of ane ½ in. of seat begetting on the peak plate. I like to go on the seat cut the same width as the wall, including the capsule.

In my model here, and on most of my jobs using ii×4 walls, the seat measures four in. with the capsule. With wider plates, you lot cannot cut into the rafter more than than a third of its overall width—this would weaken the structure too much. I generally go with four in., and it works well with most roofs.

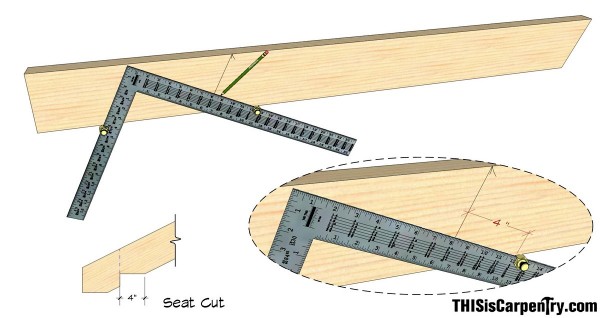

To do a 4-in. seat cut, I rotate the square 180 degrees from the plumb cuts I've marked and so far—this way the stair gauges volition exist referenced against the lesser edge of the rafter. I and so slide the square along the bottom edge until the viii in. marker on the body intersects the parallel plumb line I drew before; you'll see that the line I trace volition be exactly 4 in. long.

To me, that'southward the quickest style to describe the seat cut.

Then, while I have the foursquare in that location, information technology's easy to slide the square over to mark for the rafter'due south overhang (if I have an overhang less than 12 in.). In my case, that's 6 in., and I draw another plumb line and then I tin can starting time to cutting the rafter.

Setting the Rafters

Earlier I gear up my rafters, I like to set the ridge in position first. That'south why I recorded the Rising measurement of our rafter.

I could summate this on my structure figurer, merely honestly, I notice it easier to depict it out—it's much safer, since drawing makes it easier to keep track of the numbers. By drawing it out on a story pole, I observe the mail service meridian, and I tin then cut the story pole to post the ridge.

| To practice that, I offset with my calculated Ascent of the rafter, and measure upwards that distance from the bottom of my post. I marking that on the post, and label information technology. In this case, that measurement is 1 ft. 5 13/16 in. |  |

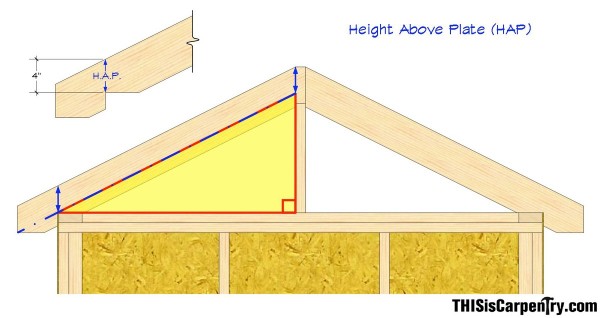

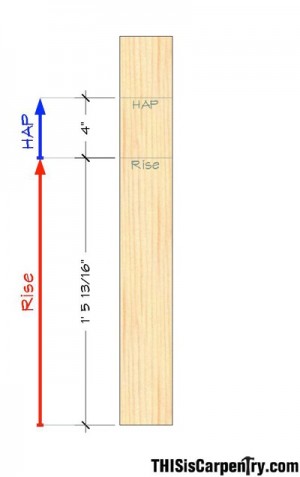

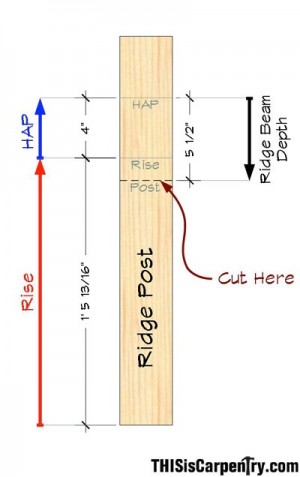

To get to the top of the ridge, I need to mensurate the rafters HAP, or "Height Above Plate." Looking at the illustration (below), y'all can see the triangle that our construction calculator calculated. The computer has no idea almost the depth of the seat cut, or the size of the rafter fabric—it's easiest to measure from the seat cut to the superlative edge of the rafter I've cut, and that is the HAP.

| I add that measurement to the Rise and label it. The post height will now exist at the top elevation of the ridge. In this example, my rafter has a 4-in. HAP. |  |

Next, since I want to mail the ridge, I measure the depth of the ridge beam (in my example, 5 ½ in.), and measure out down from my HAP line mark. This line represents the height of the post. I now know if I cut that, it will fit.

| Mathematically: (Ascension + HAP) – Ridge Beam depth = Mail service Height |  |

In real life (non mathematics), non everything is perfect. I usually deduct a one/four to ane/two in. more, to allow me to shim the ridge into position perfectly. Information technology's a lot easier to shim a 1/2 in., than to take to cutting a 1/2 in. off later on the ridge is on the mail.

The process is pretty straightforward—no complex charts or tables. And as Tom Brewer says, we all love it when a plan comes together and actually works!

(SketchUp drawings by Wm. Todd Murdock)

Source: https://www.thisiscarpentry.com/2012/11/09/common-rafter-framing/

Posted by: burkemasimed.blogspot.com

0 Response to "How To Make A Rafter Seat Cut"

Post a Comment